1,382 total views, 2 views today

Braille – language to enable the blind to read!

Braille Packaging

Braille packaging cartons enables someone with a visual impairment to read what is written on the packaging.

It is increasingly becoming a requirement for Pharmaceutical cartons across the world.

Since the medicines can be purchased over the counter (OTC), it is important to ensure the consumer is able to choose the correct product at a supermarket or pharmacy.

Process of Braille Packaging

Initially, braille packaging was done with the process of platen embossing.

A large sheet with multi-up cartons would be fed and pressure would be applied through a male+female process.

Cons of Platen Embossing (Old Technology)

– Dot reproduction is not consistent across the sheet due to uneven pressure,

– Chances of dots going missing due to male block getting damaged/worn out during production.

– the Make Ready time or set up time is very high and tricky due to the huge size of a printed sheet.

– Dot height is prone to reduction, due to the sheets being handled multiple times before supplying to the client.

Over the period of the last decade, there have been a lot of advancements in the technology used to reproduce the braille dots on printed packaging cartons.

The current technology involves a single-up rotary die that applies pressure through a male+female system across a smaller surface area, enabling better, more accurate control.

Pros of Rotary Die Embossing (Latest Technology)

– Dot reproduction control is very high across each and every carton

– In case of missing dots, the machine ejects the carton ensuring only perfect cartons are output.

– The setup time is quick and simple since only 1 carton has to be checked and adjusted through a simple pressure system.

– Dot height is better achieved, as it is applied in the final stage of carton manufacturing, and is shipped out to the client.

Requirements for accurate reproduction of braille

– Target Dot Height must be between 0.10 and 0.20 mm

– Gap between dots should be 0.12 mm

– Spacing between letters should be as a master file.

– The output should be certified by a proper certification organization to ensure no scope for error.

Industries that use Braille Packaging on cartons

Pharma – maximum usage

Cosmetics – very select usage

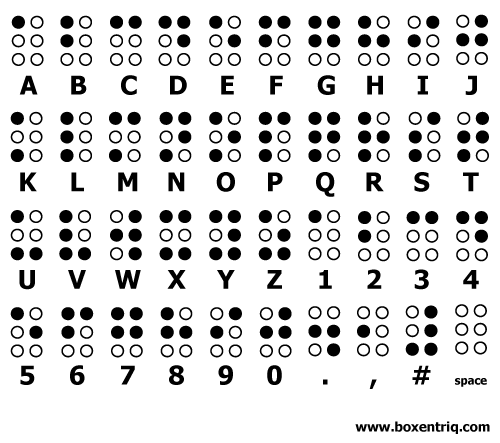

The alpha-numeric master is as shown below – GRADE 1 Braille

SAPCO has been specializing in Braille Packaging since 2005, as of 2021, we have got the latest technology of ACCU BRAILLE from BOBST.

This enables us to accurately produce dots at a speed of 200 meters/minute.

If there is an overlap or error during the machine running, the machine has a system of ejecting the faulty cartons into an ejection chute to avoid mistakes from being supplied to the client.

This can be scrapped to avoid any mix-ups.

SAPCO has the infrastructure in place, to do 5 horizontal lines/rows of Braille in 1 pass on our Bobst Expertfold Folder Gluer Carton Pasting Machine.

The below image depicts 3 horizontal rows of braille. We can do up to 20 alphanumeric letters in each row!